Artificial Quartz Stone Slab Making Machine for Polished Artificial Quartz Stone Tile Wall Floor

Artificial Quartz Stone Slab Making Machine for Polished Artificial Quartz Stone Tile Wall Floor Main machines: a. conti

Basic Info

| Model NO. | Artificial Quartz Stone Slab Making Machine |

| Type | Polishing Machine Series |

| Application | Production Line, Polishing & Grinding & Sanding, Cutting, Multi-Use |

| Artificial Stone Type | Artificial Quartz |

| Automation | Automatic |

| Control | Artificial |

| Certification | CE, ISO |

| Customized | Customized |

| Color | Yellow |

| Condition | New |

| Voltage | 220/380V |

| Warranty | One Year |

| Power | Designed as Local Power Supply |

| Tile Thickness | 6-30mm |

| Tile Usage | Hotel Countertops Kitchen Tops Bathroom Vanity Top |

| Transport Package | 1. Standard Packing 2. Packing Request |

| Specification | 12600*1950*1600mm |

| Trademark | Hongfa |

| Origin | Guangxi, China (Mainland) |

| HS Code | 8474802000 |

| Production Capacity | 500m2/Day |

Product Description

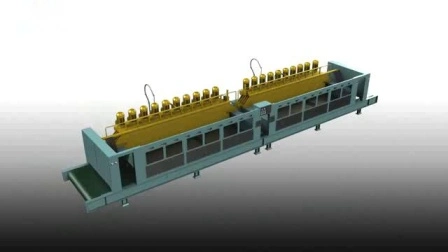

Artificial Quartz Stone Slab Making Machine for Polished Artificial Quartz Stone Tile Wall FloorMain machines: a. continuous automatic grinding machine.b. continuous automatic thickness calibrating machine.c. Vacuum vibration pressing machined.Cutting machinee. Quartz stone slab stackerf. Plate turnover machine 1. LM series continuous automatic grinding machine. LM series continous automatic grinding machine is used in process of artificial quartz stone slab. There is 4 / 12 / 16 / 20 heads difference size machine, and there is 1m / 1.7m/ 1.9m most width grinding difference desinged. The max lift range of the machine head is 100mm, which allows 50mm thickness of plate at most. The machine have been optimized and upgraded on based on combining domestic and foreign advanced technology, which enhances its lading position in the field. The machine are characterized by its unique structure of its bearing and guide bearing, automatic lubrication, being controlled and displayed by computer, automated detection and alarms reporting system about the situation of plate and abrasive, excellent performance of water and fog resistance, adjustable speed of oscillation and dransmission and being more convenient and safer to replace grinding head.

| Model | Grinding head No. | Plate max width of plate(mm) | Plate maxthickness(mm) | Total Kw | Dimension (mm) | Weight(T) |

| 8LM100 | 8 | 1000 | 50 | 100 | 7600x2700x2460 | 9 |

| 8LM170 | 8 | 1700 | 50 | 100 | 7600x3400x2460 | 11 |

| 8LM1190 | 8 | 1900 | 50 | 100 | 7600x3600x2460 | 12 |

| 12LM170 | 12 | 1700 | 50 | 150 | 9800x3400x2460 | 15 |

| 12LM190 | 12 | 1900 | 50 | 150 | 7600x3600x2460 | 17 |

| 16LM170 | 16 | 1700 | 50 | 200 | 12200x3730x2460 | 19 |

| 16LM190 | 16 | 1900 | 50 | 200 | 12200x3930x2460 | 23.5 |

| 20LM190 | 20 | 1900 | 50 | 250 | 16300x3930x2460 | 32 |

| Model | Grinding head No. | Plate max width of plate(mm) | Plate maxthickness(mm) | Total Kw | Dimension (mm) | Weight(T) |

| 4LX100 | 4 | 1000 | 50 | 70 | 5000x2800x2240 | 6 |

| 4LX170 | 4 | 1700 | 50 | 70 | 5000x3500x2240 | 7 |

| 4LX190 | 4 | 1900 | 50 | 70 | 5000x3700x2240 | 8 |

| 6LX100 | 6 | 1000 | 50 | 100 | 6200x2800x2240 | 8 |

| 6LX170 | 6 | 1700 | 50 | 100 | 6200x3500x2240 | 10 |

| 6LX190 | 6 | 1900 | 50 | 100 | 6200x3700x2240 | 11 |

| 8LX190 | 8 | 1900 | 50 | 130 | 7400x3700x2240 | 14 |

3. LY Vacuum vibration pressing machine LY series vacuum vibration pressing machine is used to press bulk material into blank plate, which contains machine frame, vacuum box, vibration motor, lifting oil cylinder, pressurized cylinder, transmission parts, vacuum parts, hydraulic electric control etc. Compare with external type compressor, it has advantages such as low power consumption, light weight, low cost etc.. The machine can make max of 60mm plate thickness, three max width spec. 1000mm, 1700mm, 1900mm.

| Model | Plate max width of plate(mm) | Plate maxlength (mm) | Plate maxthickness (mm) | Total vibrationNo. | Dimension (mm) | Weight(T) |

| LY100X250 | 1000 | 2500 | 50 | 6 | 4760x1900x2400 | 8 |

| LY100X310 | 1000 | 3100 | 50 | 6 | 5360x1900x2400 | 9 |

| LY170X250 | 1700 | 2500 | 50 | 6 | 4760x2480x2400 | 14 |

| LY170X330 | 1700 | 3300 | 50 | 6 | 5560x2480x2400 | 17 |

| LY190X330 | 1900 | 3300 | 50 | 6 | 5560x2680x2400 | 19 |

4. LQ Cutting machine LQ series cuting machine is used in vertical and holizontal cutting for the plate of quartz stone. It can make the plate pass continuously on the production line and cut down turnover of the plate. There are 4 blade and 5 blade two types according to the different thickness of plate, the plate can be cut to two part. The biggest plate can be cut into 3 sizes, 2500mm, 3100mm, 3300mm and so on, reliable guide rail and spindle structure make sure the incision straigtness, automatic control operational process, computer show data, the length and width can be adjusted within certain limits.

| Model | Plate max thicknessof plate(mm) | Plate max length (mm) | Conveyor motorpower (Kw) | Dimension (mm) |

| LQ80X250 | 800 | 2500 | 7.5 | 4150x2020x2000 |

| LQ80X310 | 800 | 3100 | 7.5 | 4790x2020x2000 |

| LQ170X330 | 1700 | 3300 | 7.5 | 5000x2920x2000 |

| LQ190X330 | 1900 | 3300 | 7.5 | 5000x3120x2000 |

Send to us